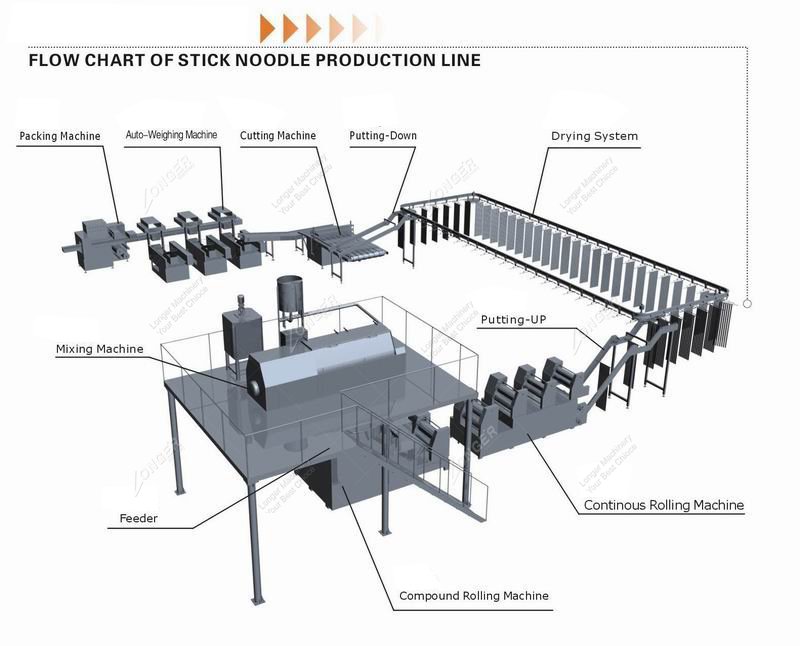

Low Temperature dried stick noodles production line, also named fine dried noodle making machines, uses vacuum mixing technology and photoelectric control technology, showing the advanced level of the domestic industry. This vermicelli production line is equipped with excellent equipment, and the whole process is highly automated, it can be operated, and production continuity is good, the product quality is excellent, the finished product rate is high, and the energy consumption is low.

1. Power supply system

1. Power supply system

| No. | Equipment Name | Model | Qty | Remark |

| 1 | Measure and Feeding Machine | LGYSJ10 | 1set | Pump 0.75kw, Volume 110L |

| 2 | Double Shaft and Speed Mixer | LGHMJ200 | 1set | Motor power 6.5/8kw, 150kg/batch |

| Falling Powder Bucket | 1pc | Stainless steel | ||

| 3 | U Type Dough Ripening Machine | LGXHJ200 | 1set | Power 4kw, 200kg/batch, 1600*800*750 |

| 4 | Compound and Continuous Dough Rolling Machine | LGMT7-50 | 1set | Slitting width 350mm, power 5.5kw+5.5kw |

| 5 | Hanging Stick Supplying Machine | LGGT450 | 1set | Power 1.5kw (frequency control) |

| 6 | Noodle Cutting Tidy Machine | LGZJQ800 | 1set | Power 1.1kw |

| 7 | Hanging Rising Machine | LGSJ350 | 1set | Power is supplied by Hang Stick Supply Machine |

| 8 | Chain Plate Drying Machine | LGPHF30 | 1set | Main power 3kw (frequency control), industrial fans 0.75 kw ×13 sets |

| 9 | Sideway Hang Down Machine | LGXJ350 | 1set | Power 1.5kw(frequency control), carbon steel. |

| 10 | Automatic Hob Cutting Machine | LGZQM50A | 1set | Noodle length adjustable 120~290mm, power 0.8kw. |

| 11 | Electric Control System | 1set |

Transmission adopts to frequency control, PLC control Domestic electrical components, not include cable |

|

| Total | Total Power ~75kw | |||

Leave Message