Automatic Wafer Biscuit Making Process

Published on Mar-20,18

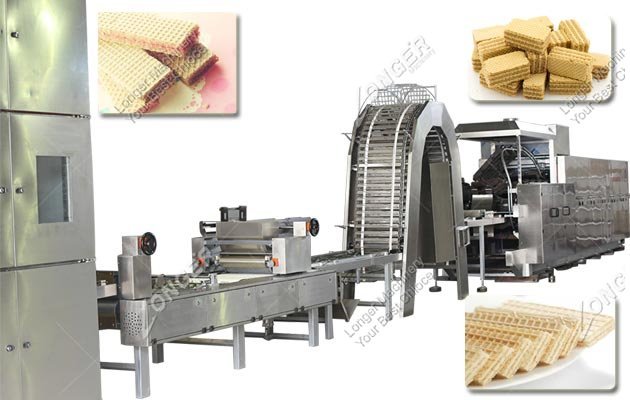

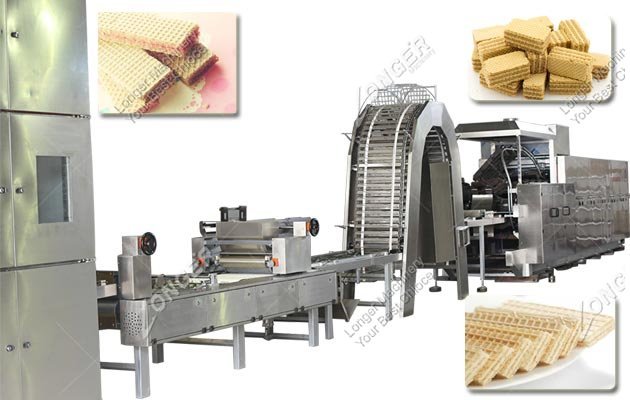

Automatic wafer biscuit making line

Automatic wafer biscuit making line is one of our most important product of LONGER company, mainly used for automatic production of various types of high-quality color, flavor and taste wafers. This wafer biscuit maker device can replace the template and wafer formula so as to produce a variety of different shapes and tastes of the wafer; also can design different shapes of the pan pattern according to the requirements of customers, the production lines can be divided into different modulus because of the different size of the production. The wafer biscuit making equipment has the characteristics of stable performance, compact structure, high output and low energy consumption, less operator, convenient maintenance, small area, no environmental pollution and so on.

Wafer Biscuit Making Process Flow: Batter Mixing - Cake Baking - Pie Cooling - Cake Coating - Cake Cooling - Cake Cutting

1. Batter Mixing: Each time 25 kg of flour and 40 kg of water are put into the batter mixer, the batter mixer is evenly stirred for about 3 to 5 minutes, and the flour and water can be mixed into a 65 L batter.

2. Cake Baking: The sizing mechanism uses intermittent batching to evenly pour the sizing onto the baking pan. The oven heats the stencil to achieve the set value through the PLC automatic temperature control system, thereby evenly baking wafers of consistent quality. sheet.

3. Pie cooling: naturally cooling the wafer pie to relieve the thermal stress of the pie slice when it is in the oven. If the pie slice can not be cooled gently, it will be easily broken even if it is affected by thermal stress.

4. Cake Coating: Set the number of layers of cream filling according to the customer's requirements. Apply evenly the cream to the cooled wafers, and then slightly pressurize them so that the cakes and creams are combined with each other.

5. Cake Cooling: The creamy wafer coated with butter is sent directly to the freezer for cooling and cooling after forming, thereby improving the temperature and humidity of the wafer cake and making it more tasteful.

6. Cake cutting: After the wafer cake comes out of the freezer, it is cut to size according to the customer's requirements.

Formulation: Formulations have a great influence on the taste of wafers. Our company will provide customers with a set of basic recipes for wafers.

If you are interested in

wafer biscuit making machine, jsut feel free to contact us.

Contact information:

Skype: serenayan666

Email: serena@machinehall.com

Whatsapp/Mobile: +8618595717505

Automatic wafer biscuit making line is one of our most important product of LONGER company, mainly used for automatic production of various types of high-quality color, flavor and taste wafers. This wafer biscuit maker device can replace the template and wafer formula so as to produce a variety of different shapes and tastes of the wafer; also can design different shapes of the pan pattern according to the requirements of customers, the production lines can be divided into different modulus because of the different size of the production. The wafer biscuit making equipment has the characteristics of stable performance, compact structure, high output and low energy consumption, less operator, convenient maintenance, small area, no environmental pollution and so on.

Automatic wafer biscuit making line is one of our most important product of LONGER company, mainly used for automatic production of various types of high-quality color, flavor and taste wafers. This wafer biscuit maker device can replace the template and wafer formula so as to produce a variety of different shapes and tastes of the wafer; also can design different shapes of the pan pattern according to the requirements of customers, the production lines can be divided into different modulus because of the different size of the production. The wafer biscuit making equipment has the characteristics of stable performance, compact structure, high output and low energy consumption, less operator, convenient maintenance, small area, no environmental pollution and so on.

Message

Your privacy is protected, please feel free to submit your inquiry to us.